Small-Batch Scaling Guide for Fashion Startups (From 15 Pieces to Repeat Orders)

If you are building a fashion brand, your first big challenge is not design — it is risk.

Most new labels fail because they over-order too early, lock money in dead inventory, and cannot adapt fast enough to what customers actually want. A small-batch approach solves this.

This guide explains how to use low MOQ production to launch smarter, protect cash flow, and scale with confidence.

Competitor-grounded market snapshot (Feb 2026)

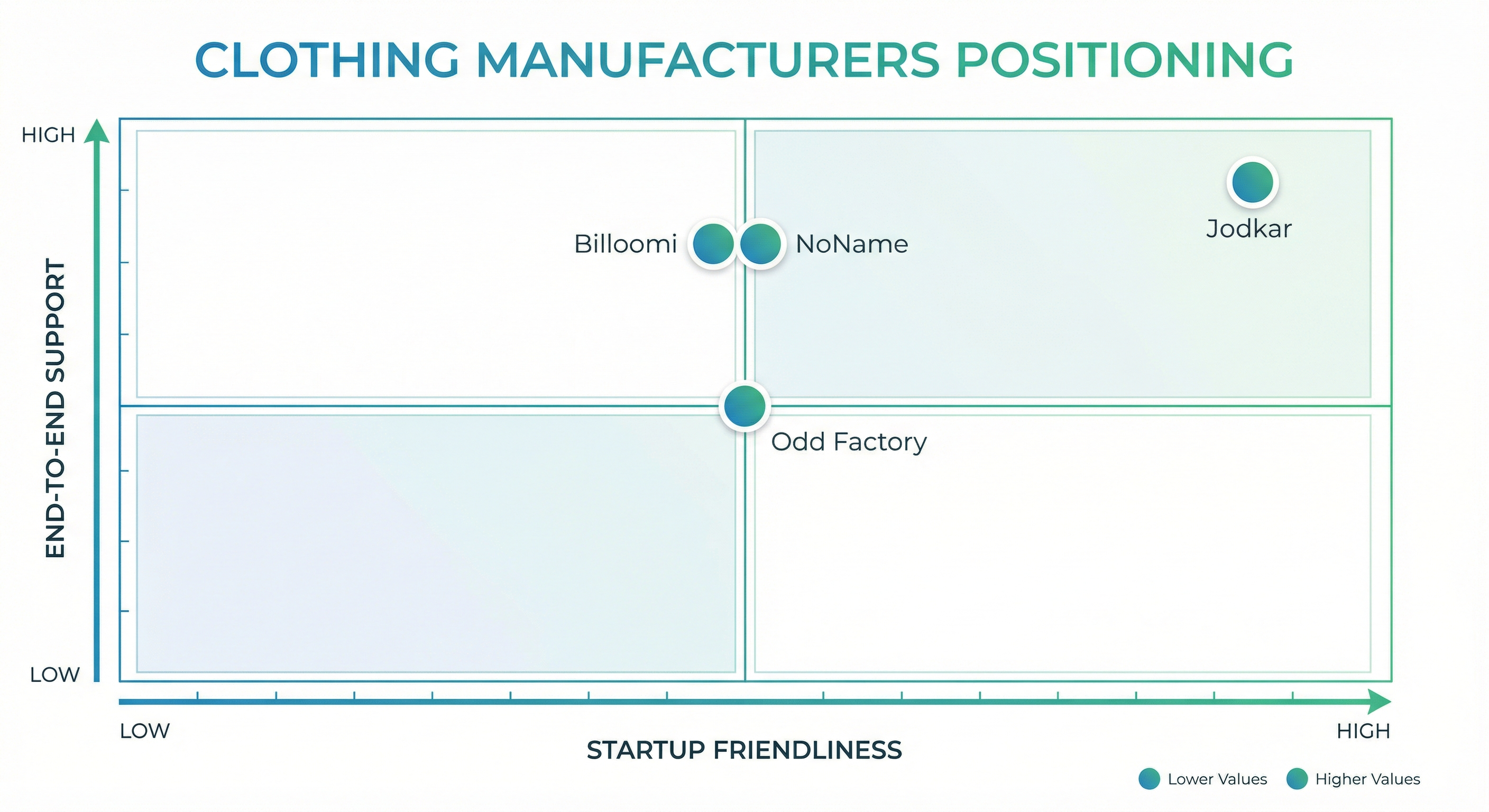

Before writing this guide, we reviewed public competitor pages to understand how startup-focused manufacturers are positioned today:

- Billoomi Fashion positions itself as a full-service export factory with compliance-heavy messaging (SEDEX/ISO), and explicitly mentions being 100% export-oriented and not supplying within India.

- NoName Global pushes startup education content strongly (for example, the “Launch Smart” angle) and publicly highlights MOQs starting at 25 pieces on the homepage, while some FAQ flows discuss higher baseline quantities depending on category/fabric.

- The Odd Factory leans into a broader “ecosystem”/consulting model and publicly lists a production MOQ around 25 units per design (with flexibility by style complexity).

The opportunity for startup founders is clear: if you can find a partner with genuinely low batch entry, strong sampling, and dependable execution, you can validate demand faster than brands locked into higher first-run quantities.

Note: Snapshot based on publicly available competitor messaging reviewed in Feb 2026.

Why small-batch wins for early-stage brands

Small-batch production helps founders reduce the three biggest startup risks:

- Demand risk: You test with real customers before going all-in.

- Cash-flow risk: You do not freeze capital in 300+ units.

- Brand risk: You refine fit, finish, and quality before scaling.

For most startup labels, a practical MOQ (like 15 pieces per color/design) is enough to validate demand while still getting professional production quality.

The 5-stage small-batch scaling framework

1) Define a focused launch capsule

Start narrow.

Choose one micro-category (for example: linen shirts, resort co-ords, occasion tops) and launch 2–4 strong styles instead of a large mixed catalog.

Your goal is not “maximum variety.” Your goal is signal clarity.

What to lock before sampling:

- customer persona and price band

- target fabric + trims

- fit intent (relaxed, structured, oversized, etc.)

- quality benchmark references

2) Build samples with production in mind

Sampling should not be treated as a cosmetic step. It is your first quality and costing control point.

Use this checklist:

- fabric behavior under stitch and wash

- seam durability and finishing quality

- comfort and drape

- fit consistency across sizes

- realistic lead time feasibility

This stage is where a good manufacturing partner helps you avoid expensive rework later.

3) Launch a controlled first batch

Produce a small first run and treat it like a live market experiment.

Track:

- sell-through in first 2–4 weeks

- returns by reason (fit, quality, expectation mismatch)

- customer feedback words used repeatedly

- conversion by style and color

Rule: Let data decide the next production move, not assumptions.

4) Scale only what proves demand

After first batch feedback:

- increase quantity only for top-performing styles

- stop weak SKUs early

- introduce one new style at a time while retaining winners

- negotiate better unit economics on repeat production

This is how brands scale without chaotic inventory growth.

5) Build repeatable operations

Once demand is validated, focus on consistency:

- standardize measurement specs and QA checkpoints

- create a production calendar around launch cycles

- maintain clear communication for approvals and revisions

- improve packaging and dispatch reliability

At this stage, your brand stops operating in “trial mode” and starts operating like a system.

Small-batch mistakes founders should avoid

- Launching too many styles at once

- Choosing MOQ based only on per-unit cost

- Skipping quality checks between sample and production

- Changing designs mid-production without impact analysis

- Not documenting learnings from each batch

Low MOQ is powerful only when paired with disciplined decision-making.

What to ask your manufacturer before you start

A strong manufacturing partner should answer these clearly:

- What is your MOQ per style/color?

- What are your sampling and production timelines?

- How do you handle QC and rework?

- Can you support custom details and revisions?

- Do you support sustainable sourcing and low-waste workflows?

Clarity here prevents delays, cost overruns, and quality surprises.

10-point small-batch launch checklist

Use this checklist before confirming your next batch:

- Define one clear customer segment (not everyone).

- Lock 2–4 hero styles for the launch capsule.

- Freeze fabric + trims before sampling starts.

- Approve fit on at least one real wear test, not only mannequin review.

- Set batch-level success metrics (sell-through %, return %, reorder trigger).

- Document per-style costing and margin floors before production.

- Run QC checkpoints at fabric-in, inline, and final inspection stages.

- Plan delivery and launch calendar backwards from campaign date.

- Prepare a reorder decision rule (what scales, what stops).

- Capture post-launch learnings in one operating note for the next cycle.

If you can check all 10, you are set up to scale with control rather than guesswork.

Final takeaway

Scaling a fashion startup is not about producing more. It is about producing smarter.

A small-batch model lets you learn fast, stay financially healthy, and build a brand that improves every cycle.

If you want to launch with low risk and scale with confidence, start with controlled batches, tight feedback loops, and a manufacturing partner built for startup realities.

At Jodkar Fashion, we help emerging brands scale through low MOQ production, precision sampling, and sustainable manufacturing practices.

If you want to plan your first or next batch, contact us.